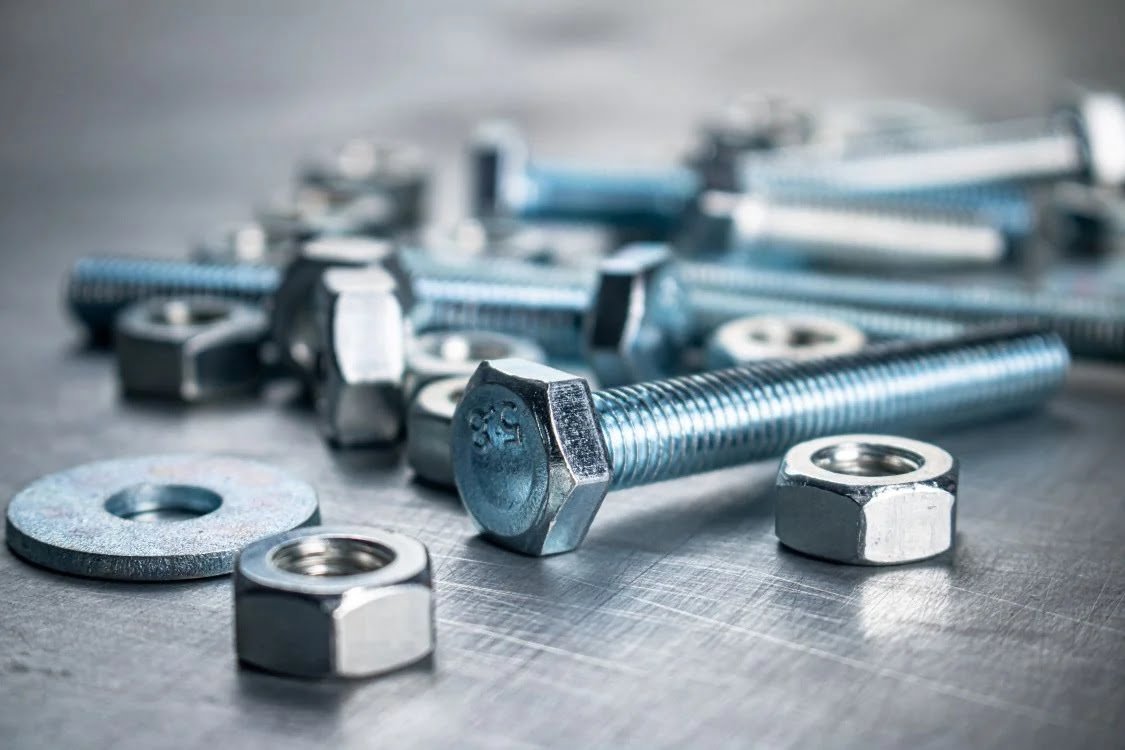

Nuts and bolts can be described as construction or manufacturing fasteners and they are usually used where screws cannot be employed. They are the unnoticed carriers of these structures and buildings. However, one gets wondering the difference between a nut vs bolt and how they are introduced in the provision of stability. Let’s break it down.

What Is a Nut?

A nut is a small bore usually of hexagonal shape, which has an internal screw thread. It is intended to be used in conjunction with another component known as a bolt with which it holds materials in place firmly. Nuts are available in different categories but are shaped differently, although the hex shape is the most universal nut available.

What Is a Bolt?

A bolt is a metal pin having external screw threads and maybe headed and has internal screw threads and maybe headed. Sometimes it has a head, typically hexagonal, on one end and it is employed to poke through the materials to be joined. A bolt always works together with a nut to allow the formation of a strong and secure joint to be produced.

How Do nut vs bolt Work Together?

The mechanism of operation of a nut and bolt attachment is actually quite basic. The bolt is passed through at a hole which is found on the material, and this is followed by the tightening of a nut on the other end. This nut screws into the other nut and as the screw draws near the other end it clamps all the materials at their meeting point hence bringing a close of connection.

Types of Bolts and Their Uses

It is important to grasp the differences between each kind of bolt so that the right type of fastener may be employed. Some of the most common types include:

- Hex Bolts: When employed in construction or in making of machines, the provide strength and endurance.

- Carriage Bolts: These have a rounded head, and are mostly applied in carpentry.

- Anchor Bolts: Made for concrete purpose, they are perfect for weight related activities such as holding of structures.

- U-Bolts: Most often employed to secure them to surfaces such as in the plumbing where pipes or rods are required.

- Lag Bolts: Most suitable for connecting wooden to wooden or wooden to metallic surfaces, thus giving good holding power.

Types of Nuts and Their Applications

Just like bolts, nuts also come in a variety of designs to suit different applications

- Hex Nuts: This one is used with the bolts of the same diameter and thread size; it is the most typical kind in use.

- Lock Nuts: Integrate a locking mechanism that will freeze the nut from loosening especially when used in vibrating machines.

- Wing Nuts: Intended for hand threading these hence making them suitable for applications that frequently needs readjustment.

- Cap Nuts: Also referred to as acorn nuts, these slide over the free end of a bolt and offer a style component.

Choosing the Right Nut and Bolt for Your Project

Selecting the appropriate nut vs bolt is essential for the success and longevity of your project. Here’s what to consider:

- Material: Select materials that are suitable for the area that the fasteners are to be applied on. Possible choices are: stainless steel; galvanized iron; and brass – with different degree of suitability for the task in respect of corrosion.

- Thread Compatibility: It is important that the two threads that are used so as to join the nut and the bolt correctly interlock. Working threads are those that have coarse threaded patterns, and these are rather easy to assemble as compared to those that are finely threaded and are stronger.

- Strength: Take into account the tensile strength that will be applicable for your project. A number of bolts are made of higher grades, which makes them more strong and resistant to shear loads.

- Environment: Where there is exposure to moisture or chemicals or this kind the project requires stainless steel bolts as these do not corrode.

Final Thoughts: The Essential Role of Nuts and Bolts

nut vs bolt may well be defined as components that are small and relatively easily recognizable but they are used in many industries. Due to their capacity of providing good and firm connections, they are used widely in construction, machinery building, automobiles and even in common use items. You will, therefore, be in a position of guaranteeing the success and safety of your projects through the consideration of the various types as well as choosing the right blend for each.